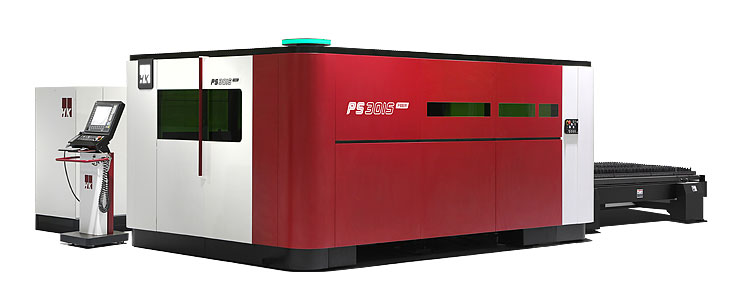

Laser Cutting Machine Germany

Examine the rough material being cut to determine if the section is straight and smooth. If you notice a deviation in the cut, adjust your equipment parameters so that the proofing meets the requirements.

GSS Machinery high-speed CO2 laser machines come in a variety of configuations to fit your budget and application processing needs.